By Govind Bhutada Graphics/Design: Athul Alexander

Breaking Down the Key Minerals in an EV Battery

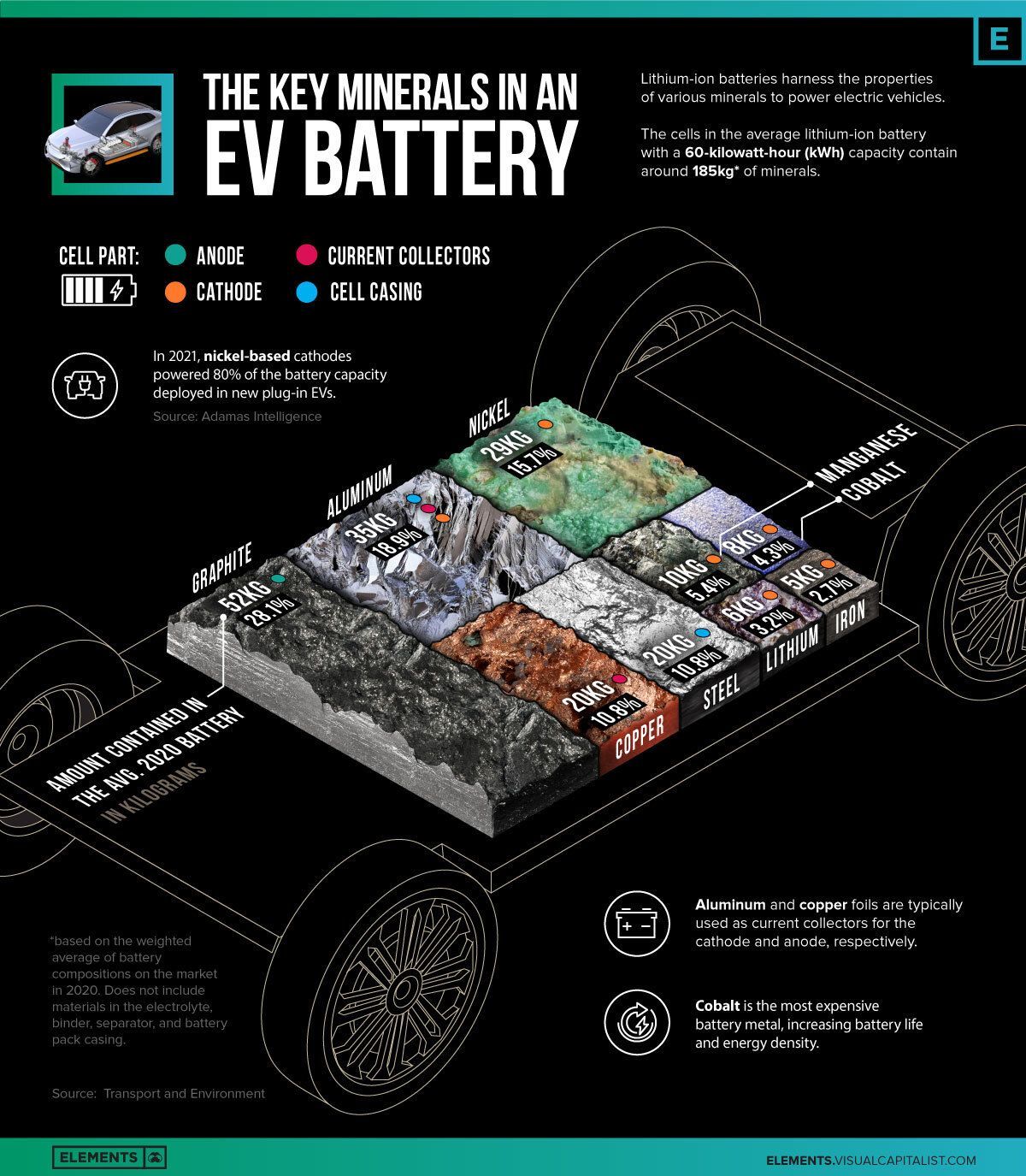

Inside practically every electric vehicle (EV) is a lithium-ion battery that depends on several key minerals that help power it.

Some minerals make up intricate parts within the cell to ensure the flow of electrical current. Others protect it from accidental damage on the outside.

This infographic uses data from the European Federation for Transport and Environment to break down the key minerals in an EV battery. The mineral content is based on the ‘average 2020 battery’, which refers to the weighted average of battery chemistries on the market in 2020.

The Battery Minerals Mix

The cells in the average battery with a 60 kilowatt-hour (kWh) capacity—the same size that’s used in a Chevy Bolt—contained roughly 185 kilograms of minerals. This figure excludes materials in the electrolyte, binder, separator, and battery pack casing.

| Mineral | Cell Part | Amount Contained in the Avg. 2020 Battery (kg) | % of Total |

|---|---|---|---|

| Graphite | Anode | 52kg | 28.1% |

| Aluminum | Cathode, Casing, Current collectors | 35kg | 18.9% |

| Nickel | Cathode | 29kg | 15.7% |

| Copper | Current collectors | 20kg | 10.8% |

| Steel | Casing | 20kg | 10.8% |

| Manganese | Cathode | 10kg | 5.4% |

| Cobalt | Cathode | 8kg | 4.3% |

| Lithium | Cathode | 6kg | 3.2% |

| Iron | Cathode | 5kg | 2.7% |

| Total | N/A | 185kg | 100% |

The cathode contains the widest variety of minerals and is arguably the most important and expensive component of the battery. The composition of the cathode is a major determinant in the performance of the battery, with each mineral offering a unique benefit.

For example, NMC batteries, which accounted for 72% of batteries used in EVs in 2020 (excluding China), have a cathode composed of nickel, manganese, and cobalt along with lithium. The higher nickel content in these batteries tends to increase their energy density or the amount of energy stored per unit of volume, increasing the driving range of the EV. Cobalt and manganese often act as stabilizers in NMC batteries, improving their safety.

Altogether, materials in the cathode account for 31.3% of the mineral weight in the average battery produced in 2020. This figure doesn’t include aluminum, which is used in nickel-cobalt-aluminum (NCA) cathode chemistries, but is also used elsewhere in the battery for casing and current collectors.

Meanwhile, graphite has been the go-to material for anodes due to its relatively low cost, abundance, and long cycle life. Since the entire anode is made up of graphite, it’s the single-largest mineral component of the battery. Other materials include steel in the casing that protects the cell from external damage, along with copper, used as the current collector for the anode.

Minerals Bonded by Chemistry

There are several types of lithium-ion batteries with different compositions of cathode minerals. Their names typically allude to their mineral breakdown.

For example:

- NMC811 batteries cathode composition:

80% nickel

10% manganese

10% cobalt - NMC523 batteries cathode composition:

50% nickel

20% manganese

30% cobalt

Here’s how the mineral contents differ for various battery chemistries with a 60kWh capacity:

With consumers looking for higher-range EVs that do not need frequent recharging, nickel-rich cathodes have become commonplace. In fact, nickel-based chemistries accounted for 80% of the battery capacity deployed in new plug-in EVs in 2021.

Lithium iron phosphate (LFP) batteries do not use any nickel and typically offer lower energy densities at better value. Unlike nickel-based batteries that use lithium hydroxide compounds in the cathode, LFP batteries use lithium carbonate, which is a cheaper alternative. Tesla recently joined several Chinese automakers in using LFP cathodes for standard-range cars, driving the price of lithium carbonate to record highs.

The EV battery market is still in its early hours, with plenty of growth on the horizon. Battery chemistries are constantly evolving, and as automakers come up with new models with different characteristics, it’ll be interesting to see which new cathodes come around the block.

Copyright © 2024 Visual Capitalist