By VVC Resources

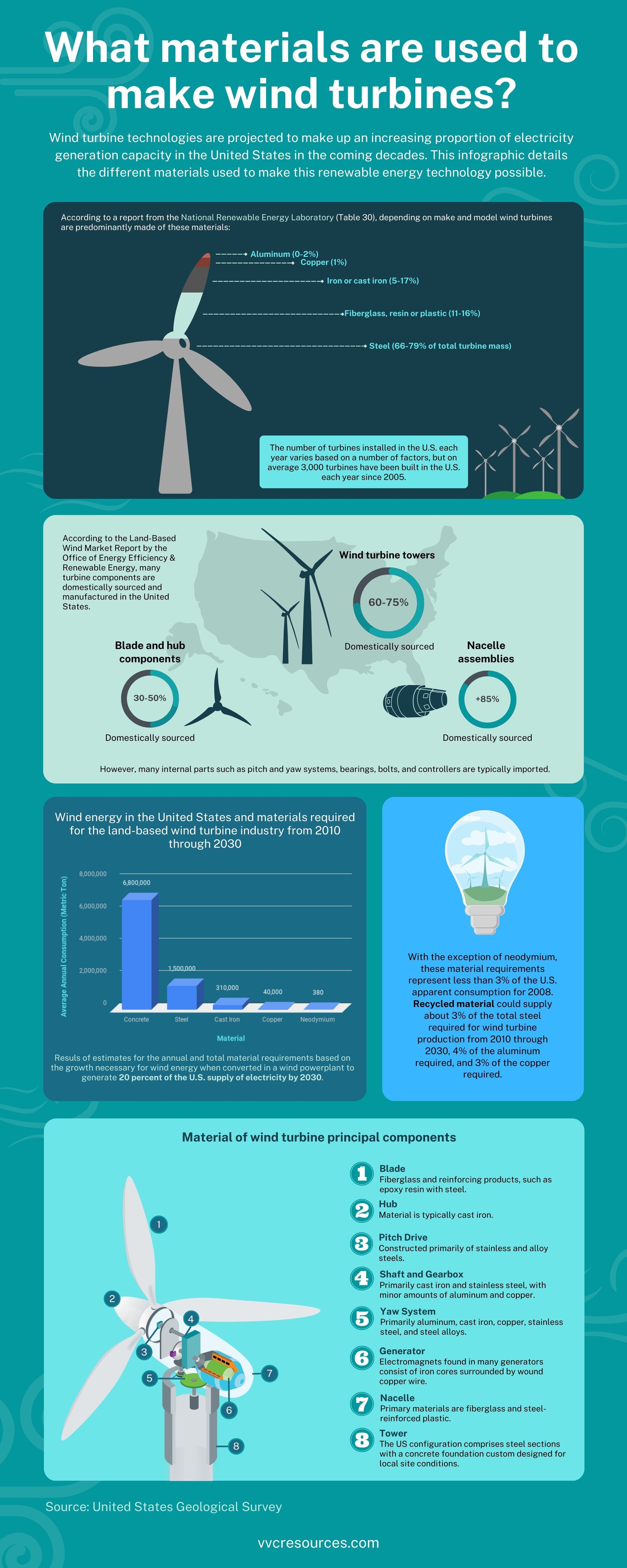

What materials are used to make wind turbines?

According to a report from the National Renewable Energy Laboratory (Table 30), depending on make and model wind turbines are predominantly made of steel (66-79% of total turbine mass); fiberglass, resin or plastic (11-16%); iron or cast iron (5-17%); copper (1%); and aluminum (0-2%).

Many turbine components are domestically sourced and manufactured in the United States. According to the Land-Based Wind Market Report by the Office of Energy Efficiency & Renewable Energy, wind turbine towers are 60-75% domestically sourced, blade and hub components are 30-50% domestic, and nacelle assemblies are over 85% domestically sourced. However, many internal parts such as pitch and yaw systems, bearings, bolts, and controllers are typically imported.

How many wind turbines are installed in the U.S. each year?

The number of turbines installed in the U.S. each year varies based on a number of factors, but on average 3,000 turbines have been built in the U.S. each year since 2005. Learn more: Wind Energy U.S. Wind Turbine Database

Wind Energy in the United States and Materials Required for the Land-Based Wind Turbine Industry From 2010 Through 2030

The generation of electricity in the United States from wind-powered turbines is increasing. An understanding of the sources and abundance of raw materials required by the wind turbine industry and the many uses for these materials is necessary to assess the effect of this industry’s growth on future demand for selected raw materials relative to the historical demand for these materials. The U.S. Geological Survey developed estimates of future requirements for raw (and some recycled) materials based on the assumption that wind energy will supply 20 percent of the electricity consumed in the United States by 2030. Economic, environmental, political, and technological considerations and trends reported for 2009 were used as a baseline. Estimates for the quantity of materials in typical “current generation” and “next generation” wind turbines were developed. In addition, estimates for the annual and total material requirements were developed based on the growth necessary for wind energy when converted in a wind powerplant to generate 20 percent of the U.S. supply of electricity by 2030.

The results of the study suggest that achieving the market goal of 20 percent by 2030 would require an average annual consumption of about 6.8 million metric tons of concrete, 1.5 million metric tons of steel, 310,000 metric tons of cast iron, 40,000 metric tons of copper, and 380 metric tons of the rare-earth element neodymium. With the exception of neodymium, these material requirements represent less than 3 percent of the U.S. apparent consumption for 2008. Recycled material could supply about 3 percent of the total steel required for wind turbine production from 2010 through 2030, 4 percent of the aluminum required, and 3 percent of the copper required. The data suggest that, with the possible exception of rare-earth elements, there should not be a shortage of the principal materials required for electricity generation from wind energy. There may, however, be selective manufacturing shortages if the total demand for raw materials from all markets is greater than the available supply of these materials or the capacity of industry to manufacture components. Changing economic conditions could also affect the development schedule of anticipated capacity.